Chemical substance management

Basic approach to chemical substance management

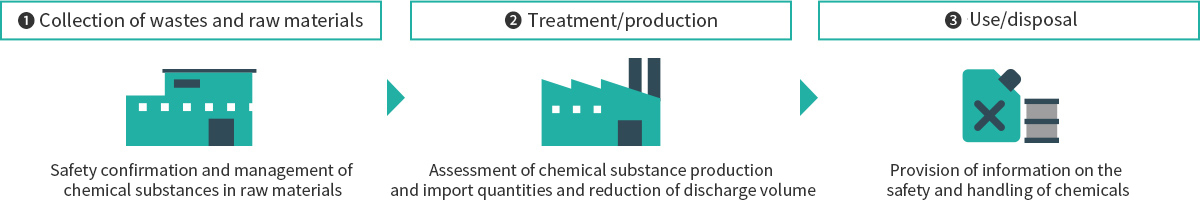

While chemical substances are indispensable in making people's lives convenient and comfortable, they present the risk of major impacts on health and ecosystems if proper management is neglected or an accident occurs. The Daiseki Group does not only comply with all relevant laws and regulations but also enforces its own management standards to engage in chemical substance safety management at every stage from product development to use and disposal.

Chemical substance management

Based on our Environmental Policy, Daiseki strives to reduce environmental impacts and prevent environmental pollution. Daiseki has its own "Poisonous and Deleterious Substances Handling Regulations", which is in line with the national Poisonous and Deleterious Substances Control Act, to prevent unauthorized use of poisonous and deleterious substances and harm to the health and safety of employees.

Initiatives at each step

① Collection of wastes and raw materials

Assessment of chemical substances in wastes and raw materials

We assess the chemical substances in collected industrial waste and used oils by obtaining waste data sheets (WDS) and other information from suppliers in advance. We also place "yellow cards" on waste collection and transport vehicles to equip employees with information including emergency treatment methods.

② Treatment/production

1. PRTR (Pollutant Release and Transfer Register) substances

We obtain SDSs to manage the chemical substances contained in the fuels and chemicals we use in treating industrial waste. We also enforce proper notifications and management of releases of PRTR substances under the relevant law in Japan*1.

In FY2024, our emissions of PRTR substances increased due to the acquisition of Sugimoto Trading Company Co., Ltd., which incinerates waste plastics and other materials, as a subsidiary.

ESG data: Volumes of PRTR substance releases and transfers

*1 Act on the Assessment of Releases of Specified Chemical Substances in the Environment and the Promotion of Management Improvement

2. Air pollutants (NOx, SOx)

We are working to reduce emissions of chemical substances that pollute the air, such as nitrogen oxides (NOx), sulfur oxides (SOx), soot, and dust. The equipment items at our company that generate soot and smoke and that fall under the Air Pollution Control Act are small boilers used in waste oil treatment processes and sludge drying equipment operated in some of our business sites.

In line with the Air Pollution Control Act and local government ordinances, all of our business sites conduct measurements of NOx, SOx, soot, and dust emissions every year. The measurements have always remained within standards at all the business sites. We are also working on the reduction of SOx, soot, and dust releases by switching boiler fuels at some business sites to city gas, propane gas, or other gaseous fuels.

ESG data: Volume of air pollution substance emissions

3. Measures to combat water pollution (BOD*1, COD*2)

The Daiseki Group complies with regulations related to the Water Pollution Prevention Act, including wastewater standards for BOD and COD. At some of our business sites, we have also set internal standards that are more strict than statutory standards for wastewater management. We manage wastewater under these strict standards.

- *1 BOD (Biochemical Oxygen Demand)

BOD indicates the amount of oxygen consumed when organic matter is broken down by aerobic microorganisms. It is the most widely used indicator for water pollution. When BOD is high, odor and other adverse effects begin to appear. - *2. COD (Chemical Oxygen Demand): An indicator of water pollution, COD is the amount of oxygen that is consumed in oxidizing and decomposing organic matter in water.

ESG data: Volume of water pollution emissions

(3) Use/treatment

Provision of data on components contained in recycled resources, etc.

For each of our business sites, the Daiseki Group prepares SDSs*3 for recycled products that we manufacture and sell, and provides this data to customers. For buyers of our recycled cement raw materials and treatment contractors handling our landfill and incineration waste, we adjust components to conform to contracted standard values and communicate the data using WDSs*4.

- *3 SDS: SDS Safety Data Sheet. An SDS describes environmental impacts, safety, handling methods, and other information concerning chemical products to prevent accidents caused by chemical substances.

- *4. WDS: Waste Data Sheet. The WDS is a form that is filled and exchanged to ensure that industrial waste received from a discharger is properly treated. The Waste Disposal and Public Cleansing Act requires that a waste discharger provide the waste properties and other information about the waste to the waste treatment provider. The Ministry of the Environment recommends the use of the WDS as a form to exchange this data.